What id horizontal directional drilling(HDD) and how it goes

- Grid Tech

- Dec 18, 2022

- 4 min read

Even directional boring (HDD) is a development technique used to introduce pipes underground without upsetting the ground surface. The drill is sent off from one finish of the planned drag way and recovered at the opposite end, and except the send off and recovering spaces over the ground, the whole interaction happens underground, hidden.

HDD has turned into a decision option in contrast to customary line-laying strategies that require opening up the world's surface up to the profundity of establishment for the whole pipeline course.

Flat directional penetrating is great for use where digging should be kept away from like under a railroad, a dike, an expressway, and underneath lakes and waterways. With cutting-edge HDD directing innovation, it is likewise now conceivable to introduce pipelines under occupied city roads without disturbing the progression of traffic and influencing organizations.

History of horizontal directional drilling

HDD can be followed back to the mid-1900s when it was found that the vertical wellbores were veering off at their own will with tendencies up to 50 degrees to the vertical. In 1926 gyrators by Sperry Company helped measure borehole tendency and azimuth.

In 1929, H. John Eastman fostered the attractive single-shot and multi-shot instruments that could gauge both tendency and bearing. This started the period of controlled directional boring, which was precise and could be deliberately digressed.

In the mid-1960s, Martin Cherrington planned his drill rig that was fundamental and lightweight.

During the 1980s, Tensor fostered a controlling innovation that opened a wide road for the use of HDD from medium-sized to extremely enormous tasks, including intersections.

Advantages of horizontal directional drilling

• HDD is a base effect technique and is particularly helpful in naturally touchy regions like wetlands, estuaries, streams, and lakes.

• A speedy and precise technique empowers the administrators to achieve respectable exactness in any event, when intersections are convoluted.

• Persistent observation and control during the activity permit administrators to explore compelled spaces between existing utility lines.

• Boring can be completed at more prominent profundities to sidestep existing utilities through and through and requires just a single sending-off the shaft at the passage point and one gathering shaft at the left point.

The HDD Cycle

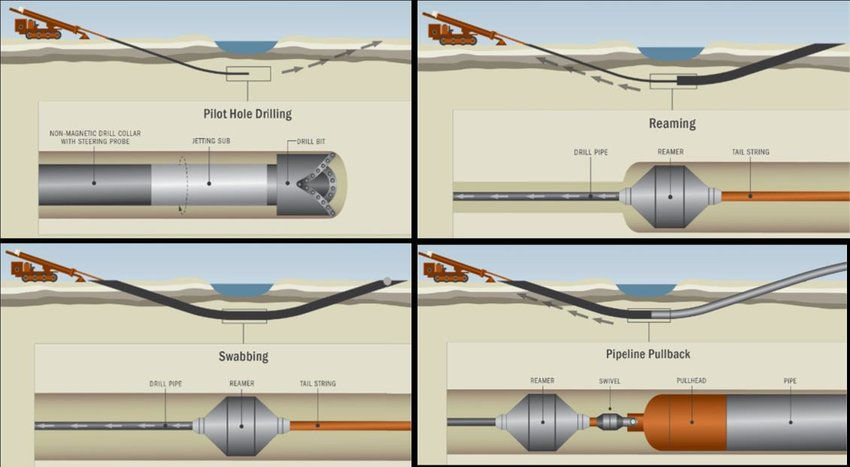

The HDD technique comprises two fundamental stages, for example boring a pilot opening and back reaming. In the wake of reaming finished, the line is gotten in through the opening.

The primary stage includes boring a pilot opening utilizing a steerable directed drill along an arranged way. The pilot opening is around 1 to 5 creeps in distance across along the proposed centerline of the line arrangement. Whenever the drill string arrives at the left point, the subsequent stage is started.

The subsequent stage includes connecting a reamer of roughly a similar size as the item line to the furthest limit of the drill string in the wake of eliminating the bore and pulling it back to the section point. In some cases, a few passes might be expected before the ideal drag breadth is accomplished.

The drag breadth is approx. half bigger than pipe breadth to empower simple get-through of the line string.

When the reamer has gone about its business, it's the ideal opportunity for the line pullback, where the item pipe is appended to the reamer and got through the borehole.

Up and down the interaction, electronic checking of the drill way is done to get the greatest level of exactness. A slurry framework circles the penetrating liquid and helps transport the drill cuttings back to the surface.

Level directional penetrating (HDD) is a moderately new broadcast communications and utility establishment innovation. It considers more superior accuracy and adaptability in the arrangement. Also, it disposes of the need for expensive digging and the requirement for enormous teams, street terminations, and different intricacies related to customary digging and line establishment.

Nonetheless, the old strategy for burrowing down to introduce lines and utilities is known as open-cut, and it is essentially more troublesome than horizontal directional drilling yet has different disadvantages. Simultaneously, flat directional penetrating for your maintenance, support, or establishment work is reasonably the most practical methodology.

Here we view a portion of the reasons regarding the reason why is it fundamental:

Perseverance

It is more challenging for HDDs to be harmed during establishment given the reception of solid materials with longer lives and better situating precision. Tragically, pipes have run under spans in certain locales, those that ride streams, presenting them to the climate and lessening their life expectancy by half to 75%.

HDD makes it simple to introduce under streams, carports, and so on and covering line and utility lines builds their drawn-out perseverance.

Level directional penetrating (horizontal directional drilling) is a somewhat new broadcast communications and utility establishment innovation. It considers more superior accuracy and adaptability in the position. What's more, it wipes out the need for exorbitant digging and the requirement for enormous groups, street terminations, and different entanglements related to customary digging and line establishment.

Notwithstanding, the old technique for burrowing down to introduce lines and utilities is known as open-cut, and it is fundamentally more troublesome than HDD yet has different disadvantages. Simultaneously, flat directional penetrating for your maintenance, support, or establishment work is logical and the most financially savvy approach.

Here we view a portion of the reasons concerning for what reason is it fundamental:

Perseverance

It is more challenging for HDDs to be harmed during establishment in light of the reception of sturdy materials with longer lives and better situating precision. Tragically, pipes have run under spans in certain areas, those that ride streams, presenting them to the climate and decreasing their life expectancy by half to 75%.

HDD makes it simple to introduce under streams, carports, and so forth and covering line and utility lines expands their drawn-out perseverance.

Decreased Expenses

HDD is speedier, which brings down the expense of capacity. As a little something extra, less soil is upset, which decreases how much land that should be re-established. Because of HDD's decreased administrator necessities, there is likewise a decrease in labor costs.

HDD doesn't depend on leasing excavators and other weighty hardware; subsequently, less gear is required. This means lower costs. Thusly, it is savvier in pretty much every manner than open-cut boring.

Comments