Beyond the Straight Path: Unleashing the Power of Directional Drilling

- Grid Tech

- Aug 6, 2024

- 5 min read

Meta-Description

Discover the world of directional drilling and its transformative impact on the oil and gas industry. From the basics to advanced techniques, this comprehensive guide delves into the why and how of steering wells toward untapped reservoirs.

Introduction

Directional drilling – it might sound like something straight out of a sci-fi novel, but in reality, it’s a game-changer in the oil and gas industry. Imagine being able to steer a wellbore precisely towards an oil reservoir that's hidden miles away, all while dodging obstacles and maximizing efficiency. That’s the magic of directional drilling. Let’s dive into this fascinating world where technology meets ingenuity and see how this technique is revolutionizing the way we extract natural resources.

The Basics of Directional Drilling

What is Directional Drilling?

Directional drilling is a sophisticated process of drilling non-vertical wells. Unlike traditional vertical drilling, this method allows drillers to reach targets that are not directly below the drill site. It involves steering the drill bit along a pre-determined path to access multiple points from a single location. This flexibility can be particularly useful in urban areas or environmentally sensitive zones where surface disturbance needs to be minimized.

Why Choose Directional Drilling?

There are several reasons why directional drilling has become the go-to method for modern drilling operations:

Accessibility: It enables access to reservoirs that are otherwise unreachable by vertical drilling.

Efficiency: By drilling multiple wells from a single site, companies can reduce the overall environmental footprint.

Cost-Effective: Fewer drilling sites mean reduced costs in land acquisition and surface preparation.

Enhanced Production: It allows for optimal positioning of the wellbore within the reservoir, improving extraction rates.

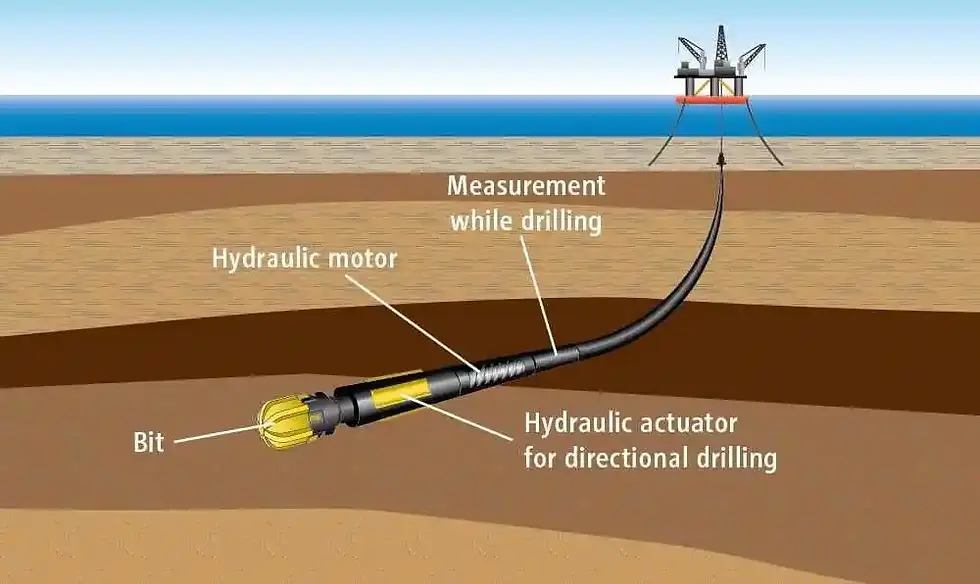

Key Components and Tools

Directional drilling involves a suite of specialized tools and technologies:

Drill Bit: The cutting tool at the end of the drill string.

Mud Motor: A downhole motor that uses the energy of drilling fluid to power the drill bit.

Measurement While Drilling (MWD): Provides real-time data on the well’s trajectory.

Steerable Systems: Allows for precise control of the drill bit’s direction.

The Evolution of Directional Drilling

Historical Perspective

The concept of directional drilling isn't entirely new. Its roots can be traced back to the early 20th century when rudimentary techniques were first developed. However, it wasn’t until the 1970s and 1980s, with advancements in technology, that directional drilling began to evolve into the sophisticated practice it is today.

Technological Advancements

Over the years, several technological breakthroughs have propelled directional drilling forward:

Rotary Steerable Systems (RSS): These systems offer continuous rotation of the drill string, improving drilling efficiency and control.

Advanced MWD and Logging While Drilling (LWD): These provide accurate real-time data on the well’s position and surrounding geology.

Hydraulic Fracturing: Often used in conjunction with directional drilling, it enhances the ability to extract oil and gas from tight formations.

Techniques and Applications

Horizontal Drilling

One of the most common forms of directional drilling is horizontal drilling. By starting with a vertical well and gradually turning it horizontal, drillers can access a larger portion of the reservoir. This technique is particularly useful in shale formations, where resources are spread out over large areas.

Multilateral Drilling

This technique involves drilling multiple lateral wells from a single vertical wellbore. Think of it as a tree with branches extending outwards, allowing for increased reservoir contact and enhanced production.

Extended Reach Drilling (ERD)

When targets are located far from the drilling site, ERD comes into play. This method involves drilling wells that extend several miles horizontally, making it possible to tap into offshore reservoirs from onshore locations.

Applications in Other Industries

While primarily associated with oil and gas, directional drilling has applications in other industries as well:

Geothermal Energy: Accessing geothermal reservoirs for sustainable energy production.

Utilities: Installing underground cables and pipelines without disrupting surface activities.

Environmental Remediation: Targeted drilling for soil and groundwater cleanup efforts.

The Process of Directional Drilling

Planning and Design

Before any drilling begins, meticulous planning and design are crucial. This phase involves:

Geological Surveys: Understanding the subsurface geology to determine the best drilling path.

Well Trajectory Design: Mapping out the well’s trajectory to avoid obstacles and maximize reservoir contact.

Risk Assessment: Identifying potential challenges and developing mitigation strategies.

Drilling Operations

Once the planning is complete, the actual drilling begins. Here’s a step-by-step overview of the process:

Spudding In: The initial stage where the surface hole is drilled.

Directional Drilling: Using steerable systems and MWD data to navigate the wellbore along the planned path.

Logging and Data Collection: Continuous monitoring and data collection to ensure the well is on target.

Completion: Once the target is reached, the well is prepared for production or further development.

Real-Time Monitoring and Adjustments

One of the key advantages of modern directional drilling is the ability to make real-time adjustments. Thanks to advanced MWD and LWD tools, drillers can receive immediate feedback and make necessary corrections to stay on course.

Challenges and Solutions

Navigating Geological Uncertainties

The subsurface is full of surprises, and not all of them are pleasant. Geological uncertainties can pose significant challenges, but advances in seismic imaging and predictive modeling are helping drillers anticipate and navigate these obstacles more effectively.

Managing Costs

Directional drilling can be expensive, especially with the high-tech equipment and expertise required. However, the long-term benefits, such as increased production and reduced environmental impact, often outweigh the initial costs.

Environmental Concerns

While directional drilling minimizes surface disturbance, it’s not without environmental risks. Ensuring proper well integrity and managing drilling fluids are critical to preventing contamination. Ongoing research and stringent regulations are key to mitigating these risks.

The Future of Directional Drilling

Innovations on the Horizon

The future of directional drilling looks bright, with several innovations poised to make the process even more efficient and effective:

Autonomous Drilling Systems: AI-powered systems that can make real-time decisions without human intervention.

Enhanced Seismic Imaging: Better subsurface imaging techniques to improve well trajectory planning.

Eco-Friendly Drilling Fluids: Developing biodegradable and less harmful drilling fluids to reduce environmental impact.

Expanding Applications

As technology continues to evolve, the applications of directional drilling are likely to expand beyond traditional sectors. From deep-sea mining to exploring extraterrestrial resources, the possibilities are endless.

FAQs

Q: How does directional drilling differ from horizontal drilling?A: Horizontal drilling is a type of directional drilling. While directional drilling encompasses various techniques for steering the wellbore, horizontal drilling specifically refers to the method of drilling a well horizontally after initially drilling vertically.

Q: What are the environmental benefits of directional drilling?A: Directional drilling reduces the number of drilling sites needed, minimizing surface disturbance and habitat disruption. It also allows for more efficient resource extraction, which can reduce the overall environmental footprint of drilling operations.

Q: Can directional drilling be used for renewable energy projects?A: Yes! Directional drilling is increasingly being used in geothermal energy projects to access heat reservoirs deep within the Earth.

Q: What role does real-time data play in directional drilling?A: Real-time data is crucial for making adjustments during the drilling process. It helps drillers maintain the desired trajectory, avoid obstacles, and optimize well placement for maximum efficiency.

Q: How has directional drilling technology evolved over the years?A: Advances in rotary steerable systems, measurement-while-drilling (MWD) tools, and seismic imaging have significantly improved the precision, efficiency, and safety of directional drilling.

Conclusion

Directional drilling has transformed the way we approach resource extraction, offering unparalleled flexibility, efficiency, and environmental benefits. As technology continues to advance, the potential applications of this remarkable technique are expanding, promising exciting developments in various fields. Whether it's tapping into hard-to-reach oil reservoirs, harnessing geothermal energy, or installing underground utilities, directional drilling is truly taking us beyond the straight path.

Comments