How Directional Drilling Company Saves Time and Money on the Construction Project?

- Grid Tech

- Aug 22, 2023

- 5 min read

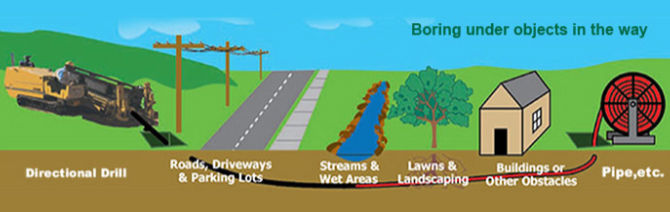

Directional drilling, often hailed as one of the unsung heroes of the modern construction industry. It is a drilling technique designed to target a specific location without needing to dig a straight vertical trench from the surface. Unlike traditional vertical drilling, this method can change the borehole's direction, providing a strategic approach to reach subsurface targets. The technique is particularly useful when obstructions exist between the starting point and the end target or when minimal surface disruption is desired.

Over the past few years, there has been a palpable shift in the construction sector towards this innovative method. A growing number of Directional Drilling Companies have sprung up, eager to harness its myriad benefits. These firms have recognized the unparalleled potential of directional drilling in streamlining projects, optimizing costs, and minimizing environmental impacts. Their increasing adoption of the technique is testament to its value, setting a new standard for efficiency and precision in the construction landscape.

The rising prominence of Directional Drilling Companies reflects a broader industry trend towards innovation and sustainability. As we delve deeper into this topic, we'll explore the multifaceted advantages of directional drilling and how it's revolutionizing construction projects globally.

Historical Perspective

For centuries, the process of drilling and excavation has been fundamental to humanity's progress, be it for accessing water, extracting minerals, or facilitating construction projects. However, the techniques and approaches have undergone significant transformation over the ages.

Traditional Construction Drilling Methods:

Open Trenching: Before the advent of advanced drilling methods, open trenching was the primary choice for laying pipelines or cables. This involved excavating large portions of the ground, leaving behind a scarred landscape. The process was labour-intensive, disruptive to the environment, and often led to extended road closures and community inconveniences.

Vertical Drilling: A straightforward method where boreholes were dug straight down. While effective for certain applications, it lacked flexibility. This rigidity meant that any subsurface obstruction required a complete re-evaluation and often relocation of the drilling site.

Pitfalls and Limitations

Both trenching and vertical drilling came with their share of challenges. They were susceptible to environmental conditions, posed significant safety risks, and their inefficiency often led to increased project timelines and escalated costs.

Innovations by Directional Drilling Companies:

Precision and Flexibility: With the development of directional drilling, companies introduced a method that allowed for precise targeting of subsurface locations. It also allows mid-course adjustments to navigate around obstacles or protect sensitive areas.

Reduced Surface Disruption: Unlike open trenching, which affected large swathes of land, directional drilling requires only entry and exit points, leaving the surface largely undisturbed. This means fewer disruptions to ecosystems, roadways, and communities.

Advanced Equipment: Directional Drilling Companies brought in state-of-the-art equipment, from advanced drill bits to real-time monitoring systems, enabling better control, faster drilling speeds, and increased accuracy.

Economic Efficiency: The minimized need for surface restoration and reduced risk of encountering obstructions led to fewer unexpected expenses. Projects became more predictable in terms of both time and budget.

The transition from traditional methods to the innovative techniques introduced by Directional Drilling Companies represents a broader evolution in the construction industry. Embracing technology and innovation, the sector has moved towards solutions that prioritize efficiency, environmental consideration, and community well-being.

The Cost and Time Efficiency of Directional Drilling

Upfront Costs: At first glance, the investment in directional drilling equipment might seem significant. However, the broader picture reveals that the high-tech machinery, while costly, eliminates the need for extensive ground excavation equipment and manpower, resulting in offset savings.

Operational Costs: Directional Drilling Companies have mastered the art of operational efficiency. Their methods require fewer personnel on-site, translating to lower labour costs. Additionally, the reduced surface disruption means less money is spent on post-operation restorations. Maintenance of the equipment, though crucial, is often less frequent and intensive than traditional drilling rigs, further trimming operational expenses.

Project Duration: One of the standout benefits of directional drilling is speed. Bypassing obstructions, eliminating extensive ground preparations, and the ability to drill under existing infrastructure dramatically accelerate project timelines. Faster completion not only means reduced labour and equipment rental costs but also quicker returns on investment.

Environmental and Logistical Advantages

Minimal Disruption: In bustling urban environments, the chaos of construction can be a significant hindrance. Traditional methods often require vast areas to be cordoned off, disrupting traffic and daily routines. In contrast, directional drilling, with its pinpoint accuracy, demands a smaller footprint. By drilling beneath structures and roads without disrupting them, urban life continues undisturbed, preserving both the aesthetic and functional elements of cityscapes. This also ensures that local ecosystems, often delicate in urban zones, face minimal disturbance.

Reduced Restoration Costs: Once traditional excavation or trenching concludes, the subsequent restoration phase kicks in, a costly and time-consuming process. Rebuilding roads, replanting green areas, and restoring other utilities can escalate budgets. Directional drilling sidesteps most of these challenges. With limited surface disturbance, the post-drilling restoration process becomes significantly simpler and more economical. The reduced environmental impact also means fewer potential fines or mitigation expenses for environmental damages.

Safety Considerations: One of the paramount concerns during any construction project is safety. Directional drilling shines in this regard. The reduced need for open trenches means fewer risks of cave-ins or accidental falls. The contained nature of the process also diminishes the chances of inadvertently damaging surrounding utilities, thereby preventing hazardous situations like gas leaks or electrical faults. Directional Drilling Companies prioritize these safety measures, ensuring the well-being of both workers and the general public.

How Directional Drilling Companies are Pioneering the Future

Innovations and Advancements: Directional Drilling Companies are at the forefront of technological evolution. They have been investing in R&D to develop more efficient drill bits, advanced navigation systems, and real-time monitoring tools. These innovations not only enhance precision but also minimize potential environmental impact. Recent breakthroughs, such as AI-driven predictive analysis, allow these companies to forecast and counter challenges even before they arise, making the drilling process smoother and more reliable.

Predictions for the Future: The construction landscape is rapidly evolving, and the role of Directional Drilling Companies is poised to expand. As urban areas become denser and the emphasis on environmental preservation grows, these companies will become indispensable. They offer solutions that are both sustainable and efficient, aligning with global trends towards green construction and reduced carbon footprints.

Moreover, as infrastructure needs grow, especially in emerging economies, these companies will be pivotal in ensuring projects are completed with minimal disruption and maximum efficiency.

Conclusion

In the ever-evolving landscape of construction, Directional Drilling Companies have emerged as game-changers. Marrying cutting-edge technology with seasoned expertise, they have revolutionized how we approach subsurface projects. By slashing timelines, diminishing costs, and prioritizing environmental stewardship, these trailblazers aren't just constructing for today but are paving the way for a smarter, more sustainable tomorrow.

If time, budget, and eco-consciousness are on your project's agenda, then partnering with a Directional Drilling Company is not just a choice; it's a future-focused investment.

Comments