How to do drilling pipe conduit wire installation

- Grid Tech

- Nov 19, 2022

- 4 min read

Because schedule 40 PVC conduit is less expensive and has a bigger internal diameter, pulling wires through it is simpler for drilling pipe conduit wire installation. Even though Schedule 80's polyethylene is thicker than Schedule '40s, Schedule 40's conduit has a lower interior diameter due to its same exterior diameter. In high-traffic areas and any other places where it might be damaged, such as behind a woodpile, Schedule 80 conduit should always be installed. For both Schedules 40 and 80, the fittings (such as adapters and turns) are the same.

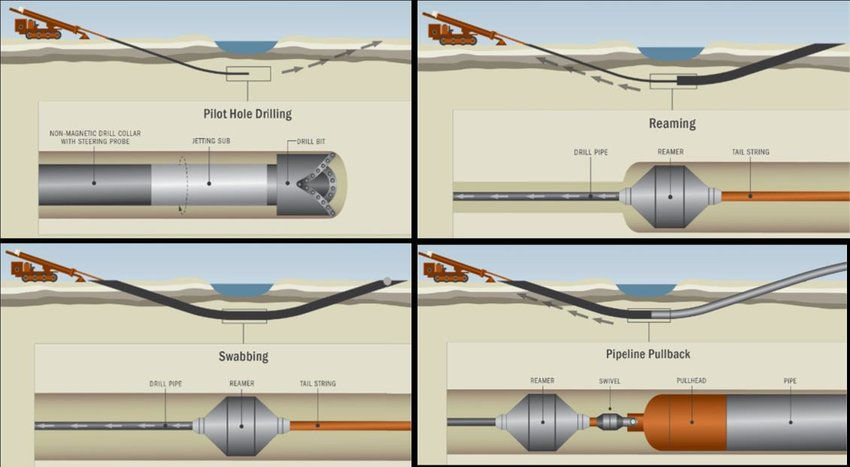

The steps to take to safely install pipes, conduits, and wires are as follows:

With PVC Conduit, Use THHN

While drilling pipe conduit wire installation, when dragging wire through PVC conduit, THHN (thermoplastic high heat-resistant nylon-coated) is the best option. Other types of wire are covered in a clingy rubber covering that makes pulling them nearly impossible. The majority of commercial jobs use stranded THHN because it is easier to pull and doesn't spring back when pushed into an electrical box than solid wire.

Using a utility knife, deburr PVC conduit

Don't forget to deburr the inside of the cut edge if cutting the PVC conduit results in a rough edge before drilling pipe conduit wire installation. The insulation on the wires can be harmed by burrs. Although there are many expensive deburring tools available, it's just as simple to smooth out the conduit's interior with a utility knife.

Utilize larger electrical boxes and PVC conduit

Instead of using 1/2-in. PVC conduit, use 3/4-in. If you have a long and twisting line if you need to fit more than three wires through one section of conduit, if you think you might need to add more wires in the future, or if you need to. It doesn't cost much more to use 3/4-in. conduit, and pulling wire through it is considerably simpler. Use a conduit that is no more than 40% full of cables, regardless of its size.

For drilling pipe conduit wire installation single-gang electrical boxes will function, however, double-gang boxes should be used if there are two or more conduit sections connecting to one box. There isn't much room inside the box for gadgets because the male connectors on the ends of the PVC conduit take up a lot of space. Deeper (2-1/8 in.) boxes fit GFCI outlets and other large devices like dimmers better.

Primer Is Not Necessary for PVC Conduit

Primer is necessary for drilling pipe conduit wire installation, although it is not necessary when gluing conduit and fittings. The right adhesive or cement is typically available in home centers close to the PVC conduit and fittings.

Make the most accurate measurements you can to prevent dry-fitting your connections. Contrary to PVC plumbing pipes, PVC conduit and fittings can be challenging to separate after being pressed together. Additionally, always put on gloves to protect your hands from the glue.

Install PVC Conduit and Electrical Boxes One Run at a Time

It may be tempting to run the conduit first, then attach all of the electrical boxes to the walls and ceiling. It is simpler to fasten one box before running the conduit to the next. After attaching the second box to the conduit, connect it to the wall or ceiling. Afterward, you won't have to struggle with the conduit as you try to bend it into place. This is crucial since it's challenging to bend short portions of PVC conduit when there are two boxes near one other. This procedure makes it simpler to glue the PVC conduit to the connector after the connectors, nuts, and bushings have been attached to the electrical box.

PVC Conduit and Metal Hangers

PVC conduit works well with metal hangers since they are more durable than plastic. Select a single-hole design. In comparison to the two-hole strap, one screw provides more than enough support, and installation is twice as quick.

If you use a hanger that offsets the PVC conduit the same distance from the wall as the knockout on your electrical boxes, the installation will look nicer. The maximum distance between supports for PVC conduit that is 1/2 in. through 1 in. is 3 ft.

PVC conduit can be cut with a circular saw.

There are many methods for cutting PVC conduit, but a circular saw equipped with a metal blade provides a quick, burr-free, smooth cut. Regular construction blades will work if you don't have a metal blade, but you might need to deburr the conduit end after you cut it.

When using PVC Conduit, use Metal Locknuts.

Because plastic locknuts can break and strip out, use metal conduit locknuts when installing PVC conduit for the drilling pipe conduit wire installation.

Limit the number of PVC conduit elbows to 360.

Consider using junction boxes to break up a long stretch of PVC conduit if it has many twists and bends. Wire pulling becomes more challenging with each elbow you place. adding turns that total more than 360? On a single run, (four 90? elbows) are not permitted. Do pros hardly ever exceed 180? because it is simpler to draw the wire a shorter distance and build an additional electrical box.

To let water out, drill a hole in the electrical box.

In the process of drilling pipe conduit wire installation an electrical box that is waterproof occasionally gets wet. Drilling a 1/4-inch hole in the bottom of the box is a good idea so that water can escape if it gets in. Before or after installing the box, you can drill the hole.

How to Pull Electrical Wires Expertly

Electrical wires are simple to push over small lengths, but most electricians pull them over longer ones in the following manner: First, remove two wires' 4 in. of sheathing. Then, cut the two exposed wires' strands in half (less bulk to pull through). Then, pass the remaining exposed wires through a fish tape's eyelet (aka draw wire or draw tape). Last but not least, cover all three wires with electrical tape up to the fish tape eyelet.

Bushings Inside PVC Conduit Guard Wires

Wires can still sustain damage if they are pulled past the edges of your PVC conduit, even if the cut end has been deburred. A bushing offers the wires a nice, rounded, smooth surface to slide by. The electrical inspector will be impressed by how inexpensive the insurance is.

Use outside weatherproof electrical boxes.

For drilling pipe, and conduit wire installation installs bell boxes, or weatherproof electrical boxes, outside. For a connection that is resistant to water, weatherproof boxes, unlike conventional boxes, typically contain threaded knockout holes. The holes that you don't utilize are often covered with caps. Make sure the box you purchase has holes in the appropriate places.

Comments