How to Save Money Without Compromising Safety in Underground Wire Installations?

- Grid Tech

- Sep 4, 2023

- 5 min read

When it comes to implementing electrical projects, particularly underground wire installations, two factors dominate the conversation: cost and safety. It is quite easy to assume that cutting costs means cutting corners, which could compromise safety.

But what if you could achieve a balance between the two without sacrificing either?

The prospect of an affordable and safe underground wire installation project is not just a pipe dream but a reality that can be achieved with thoughtful planning, the right materials and proper execution.

This blog aims to be your comprehensive guide on how to navigate this delicate balance, ensuring your project is both budget-friendly and inherently safe.

So, read on to uncover the essential steps, from initial planning to project completion, that can help you save money without jeopardizing safety.

Choose the Right Materials

Choosing the right materials for an underground wire installation project is crucial for both cost-efficiency and safety. Two key aspects to focus on are the quality of insulation and the durability of materials.

Insulated Cables:

The insulation of the cables plays a pivotal role in the project's overall safety. Skimping on costs by opting for low-quality insulation is a gamble that can result in electrical faults or, worse, fires. Therefore, it's imperative to choose cables that have undergone rigorous testing and meet all industry standards. Investing in high-quality insulation safeguards against potential hazards, ensuring long-term safety.

Long-lasting Materials:

The durability and weather-resistance of materials mustn't be overlooked. While it may seem cost-effective to go for cheaper options initially, the long-term maintenance and replacement costs can be considerably higher. Using durable, weather-resistant materials minimizes the need for frequent repairs or replacements.

So, an initial investment in high-quality, rigorously tested insulated cables and durable materials may seem expensive but pays off in the long run by lowering maintenance costs and enhancing safety.

Initial Planning is Crucial

The importance of initial planning in an underground wire installation project cannot be overstated. Before any digging or wiring begins, two essential steps should be meticulously completed: conducting a feasibility study and obtaining the necessary permits and clearances.

Conduct a Feasibility Study:

A feasibility study serves as a roadmap for the project, helping you foresee potential issues before they become problems. This preliminary investigation scrutinizes factors like soil conditions, potential interference with existing structures or utilities, and cost estimates. It helps you determine whether the project is viable and what measures need to be taken to ensure safety. For instance, the study could reveal that a particular type of soil requires special types of insulation for the wires. This foresight is invaluable in mitigating risks and avoiding costly modifications later in the project.

Obtain Necessary Permits and Clearances:

The second crucial step is to secure all necessary permits and clearances. These might include local, state, or even federal authorizations, depending on the scope and location of the project. Acquiring permits ensures that your project complies with safety regulations and zoning laws. While the process of obtaining these permits incurs expenses, they are nominal compared to the potential legal ramifications of proceeding without them. Legal troubles can not only delay your project significantly but can also result in steep fines or legal fees, eroding your budget.

Therefore, robust initial planning through a feasibility study and securing permits lays the foundation for a project that is both cost-effective and safe. It’s a small investment upfront that can save you significant time, money, and stress in the long run.

Hire Qualified Professionals

The decision to hire qualified professionals for your underground wire installation project can greatly impact its overall success, from both a safety and cost perspective. Here are some key considerations:

Credentials and Experience:

Professionals with proven experience are less likely to make errors, resulting in a smoother, more efficient project timeline. This minimizes the likelihood of costly revisions or do-overs.

Experienced contractors are well-versed in safety protocols, reducing the risk of accidents or unsafe installations that could have legal and financial repercussions.

Skilled labour can complete tasks more quickly without compromising on quality. The shorter the project duration, the less you spend on labour costs, thereby enhancing cost-effectiveness.

Training and Equipment:

A crew that has undergone rigorous training will be familiar with best practices for installation, thereby ensuring the job is done right the first time.

The right equipment not only speeds up the process but also enhances safety. For instance, a high-quality cable puller will install wires more efficiently and safely than makeshift methods.

Inadequately trained personnel using subpar equipment can result in delays and safety compromises, which ultimately escalate costs due to revisions and potential medical or legal bills.

Adequate safety equipment is a non-negotiable aspect. Professionals should be equipped with the proper safety gear to prevent injuries, thereby eliminating potential medical and legal costs for you.

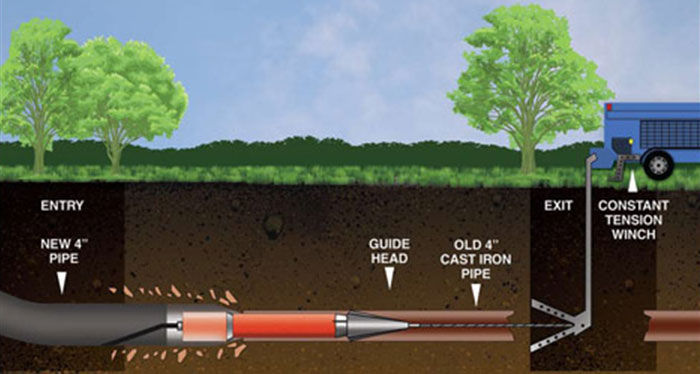

Consider Trenchless Technologies

Trenchless technology offers a less invasive method for underground wire installation. Though the upfront cost may be higher, it often results in quicker installation times and less damage to the surrounding area, thereby saving money in the long run.

Regular Maintenance and Inspection

Maintenance Schedule:

Establishing a regular maintenance schedule can help detect problems early on, allowing you to deal with them before they escalate into major issues.

Inspection:

Hire qualified inspectors to check the installation at regular intervals. It might seem like an added cost, but it's a safety measure that can save you money in the long run by preventing costly accidents and faults.

Bulk Purchasing and Negotiations

Buying materials in bulk often leads to better deals. Negotiate the prices not just for materials but also for professional services. Just ensure that the discounted services or materials do not compromise on quality and safety standards.

Leverage Technology

Use modern project management and CAD software to plan and monitor your project effectively. Proper planning can prevent cost overruns and ensure that safety parameters are met.

Recycling and Waste Management

Consider recycling old materials like wires and conduits. Some companies buy scrap metal, and the proceeds can offset some of the project costs. Additionally, proper waste management is not only good for the planet but can also help you avoid fines.

Conclusion

Undoubtedly, balancing cost-effectiveness with safety in underground wire installations may seem like walking a tightrope. However, as we've explored, it's entirely possible with meticulous planning, informed choices, and ongoing vigilance.

Key to this is starting off with a thorough feasibility study, choosing materials that are both durable and safe, and employing skilled professionals who are well-equipped for the job. Incorporate modern technologies like trenchless installation and project management software to streamline the process. And never underestimate the power of regular maintenance and inspection to avert crises before they escalate.

Remember, the initial cost should never be your only consideration; the long-term benefits of a well-executed, safe, and robust underground wire installation far outweigh the allure of short-term savings.

So, make smart choices, plan carefully, and your underground wire installation project can be a win-win situation: affordable and, most importantly, safe.

Comments